What are SIPS?

Structural Insulated Panels (SIPs) are changing the way we construct buildings, offering excellent energy efficiency, durability, and design versatility.

What are SIPS?

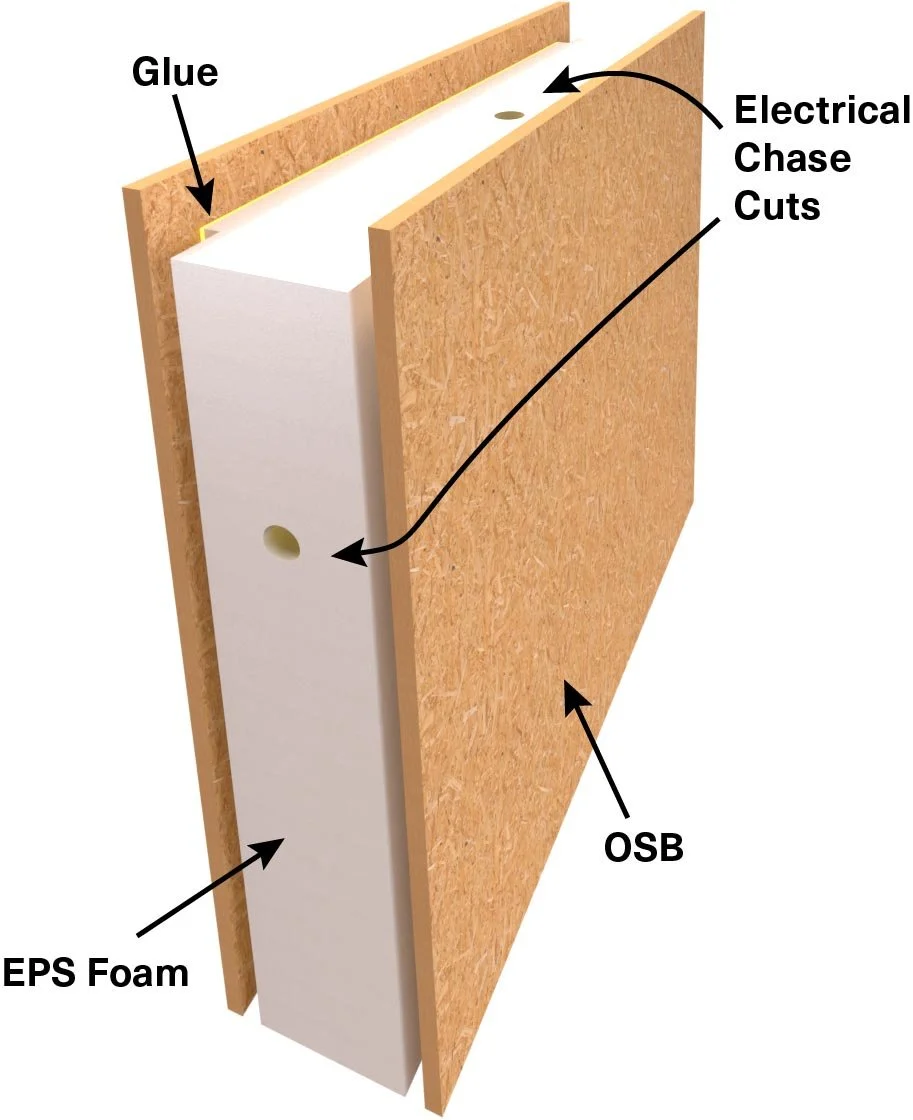

SIPs are prefabricated panels consisting of a rigid foam insulation core sandwiched between two structural facings, often made of oriented strand board (OSB). This unique composition results in a single, integrated component that serves as both the structural framework and insulation for a building.

One of the key advantages of SIPs is their exceptional thermal performance. The solid foam insulation core ensures a highly efficient and airtight building envelope, minimizing energy loss due to thermal bridging. This allows buildings constructed with SIPs to significantly reduce heating and cooling costs, providing long-term savings to homeowners and reducing their carbon footprint.

Structural Benefits

Moreover, SIPs offer remarkable structural integrity. The combination of the foam core and the OSB facings creates an incredibly strong and rigid composite material. SIPs can withstand heavy loads, making them ideal for large spans and multi-story constructions. Their inherent strength also makes them highly resistant to earthquakes and extreme weather events, providing a higher level of safety for occupants.

Design Flexibility

SIPs also exhibit excellent design flexibility. They can be customized to suit various architectural styles, accommodating a wide range of floor plans, roof designs, and exterior finishes. With SIPs, building professionals have the freedom to create unique and aesthetically appealing structures, making these panels an attractive option for both residential and commercial buildings.

Another advantage of SIPs lies in their fast and efficient installation process. These panels are precisely designed and factory-cut to meet precise specifications, allowing for quick and accurate assembly on-site. Construction time is significantly reduced, minimizing labor costs and accelerating project completion. Furthermore, the simplicity of SIP installation enables contractors to easily incorporate other building systems, such as electrical, plumbing, and HVAC, into the panel's pre-cut channels, streamlining the overall construction process.

Environmental Pros and Cons

It can certainly be argued that SIPs contribute to a more sustainable and environmentally conscious approach to building. The materials used in SIPs are often sourced from renewable resources, minimizing their environmental impact. Additionally, the enhanced thermal efficiency and airtightness of SIPs reduce the reliance on heating and cooling systems powered by fossil fuels, further reducing the building's carbon emissions.

The primary downsides would include the use of petroleum based foams, typically polystyrene, that need to be treated with brominated flame retardants. While the use of this foam has a long-term end use, it does require chemical inputs that are highly undesirable. So there is a trade-off for the higher thermal performance of standard SIPS that some may prefer to avoid. Higher performance can also be achieved via other, less toxic, construction methods.

SIPS are here to stay

Offering exceptional energy efficiency, strength, design flexibility, and to a degree, environmental sustainability, SIPs are redefining the way house are being built. As we strive for greener and more sustainable structures, SIPs will continue to play a crucial role in shaping the future of the construction industry, and ideally, over the long run, we will develop more widely sustainable, less chemically dependent, SIPs products, like straw bale SIPs.

What do you think about SIPs?

Are you considering a SIPs build? If so, please comment below and tell us about your project and thinking around SIPs.